A Temporary 4th Axis on the Mill

Ed Hollingsworth

Omaha, Nebraska

So I have this old Triumph motorcycle

I've been working on. After more than 30

years stored in my garage, I thought it deserved a little attention and maybe a

new chance at seeing the open road again. With due consideration, I finally decided not

to do just a casual fix-up—I’d do a complete top-to-bottom rebuild of the bike.

As part of the normal research necessary

with this kind of rejuvenation, I stumbled across an interesting bit of obscure

Triumph lore. Among the old heads who

care about these things, it’s a widely held belief that there was a bit of a

botched redesign of part of the valve train on these machines back in the late

60s. For a few years, some models left the factory with certain features

of the new design missing, and my bike was one of those affected. One of

these missing features was oil grooves on the spindles that hold the valve rocker

arms on the vertical twin pushrod engine. This could lead to poor

lubrication of the pushrod ends and the valve stem tips. Many owners

today who know about this just chalk it up to part of the charm of these old

machines, and live with it.

On the other hand, I had just bought this new (to me) milling machine and,

having told my wife how useful it was going to be, I was looking for a

project to use it on. I decided as part of the rebuild to put oil grooves

on the Triumph's rocker spindles.

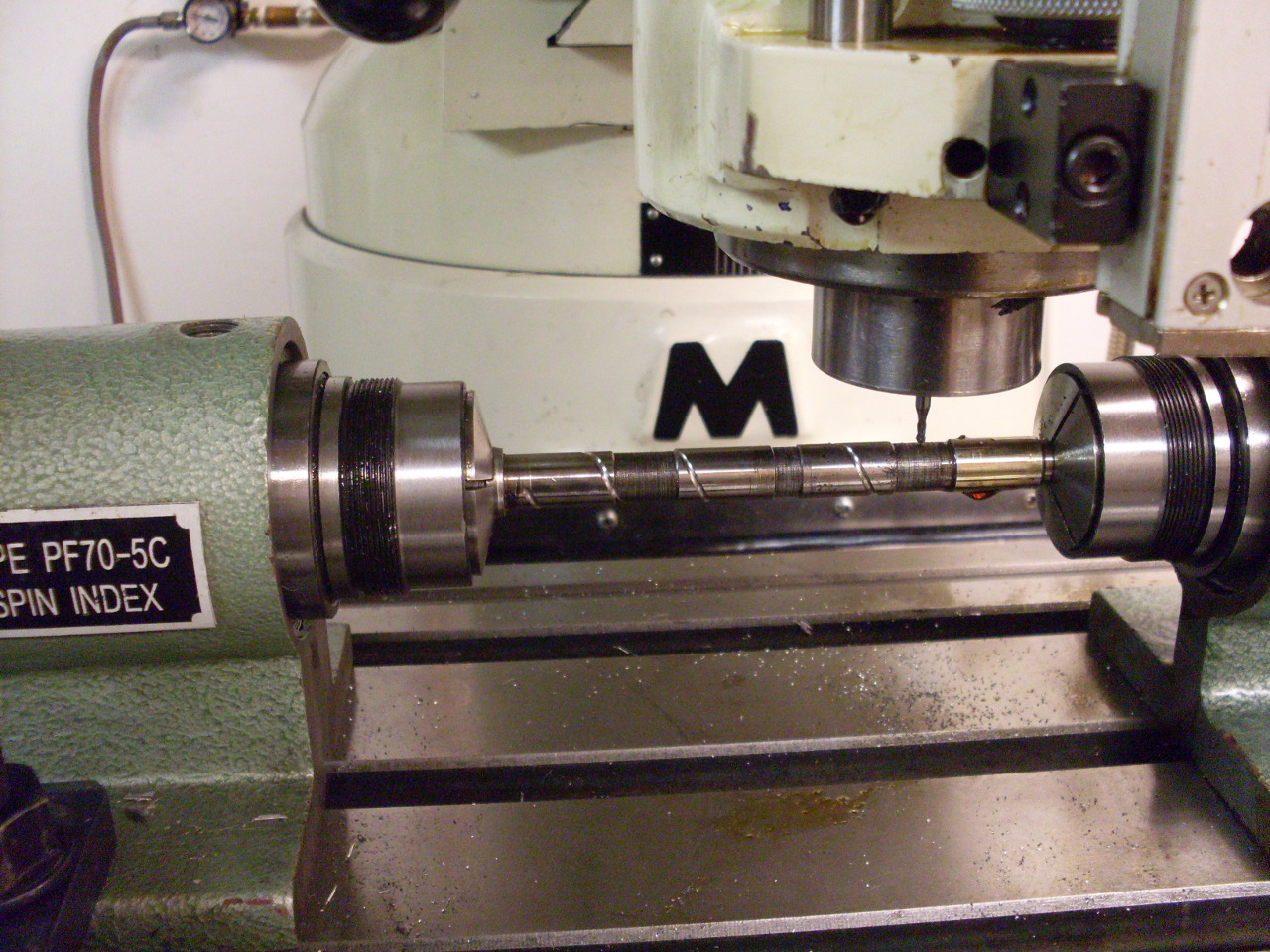

The

pic to the left shows what the 42-year-old spindles look like (click in

this and all other pics to see a larger view). They still

measure within spec, so I can't justify new ones (and new ones don't

have

grooves, either, since the factory never acknowledged the mistake).

The

picture doesn't show them, but the shaft is drilled through its length,

and

there are oil feed holes in each of the three areas of reduced

diameter. Oil is

fed into the center reduced area, and exits the other two, which are in

the

center of each rocker arm. The working surfaces are 7/16"

diameter.

The

pic to the left shows what the 42-year-old spindles look like (click in

this and all other pics to see a larger view). They still

measure within spec, so I can't justify new ones (and new ones don't

have

grooves, either, since the factory never acknowledged the mistake).

The

picture doesn't show them, but the shaft is drilled through its length,

and

there are oil feed holes in each of the three areas of reduced

diameter. Oil is

fed into the center reduced area, and exits the other two, which are in

the

center of each rocker arm. The working surfaces are 7/16"

diameter.

Judging from later model years, it appears that Triumph

had intended spiral grooves on the spindles, so that’s what I decided to do. The

problem is this would require a 4th axis in the mill, which it didn't have.

The rotation of the fourth axis would have to be coordinated with travel

down the length of the shaft. Since mine

is a manual machine, I’d have to do this mechanically.

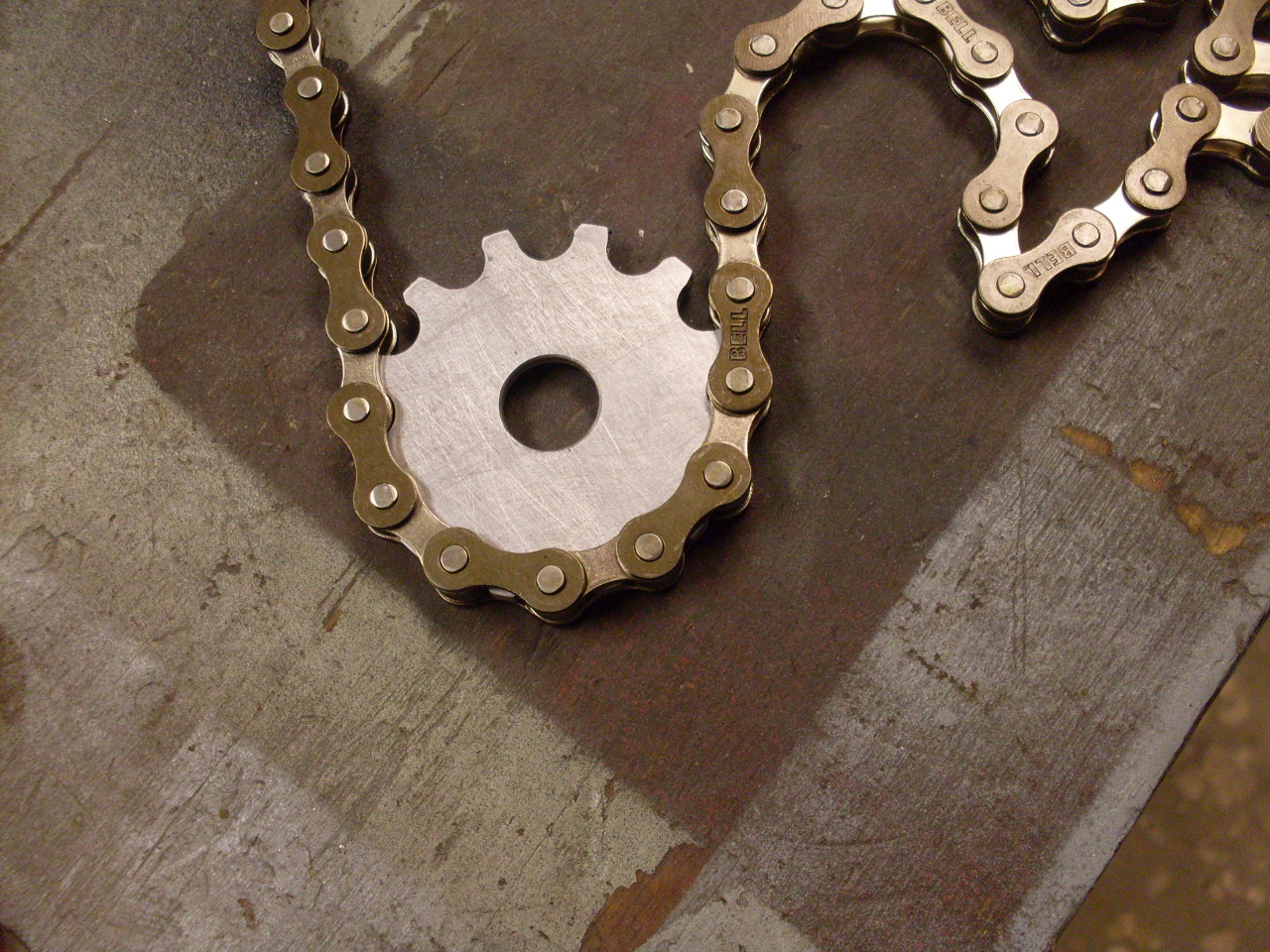

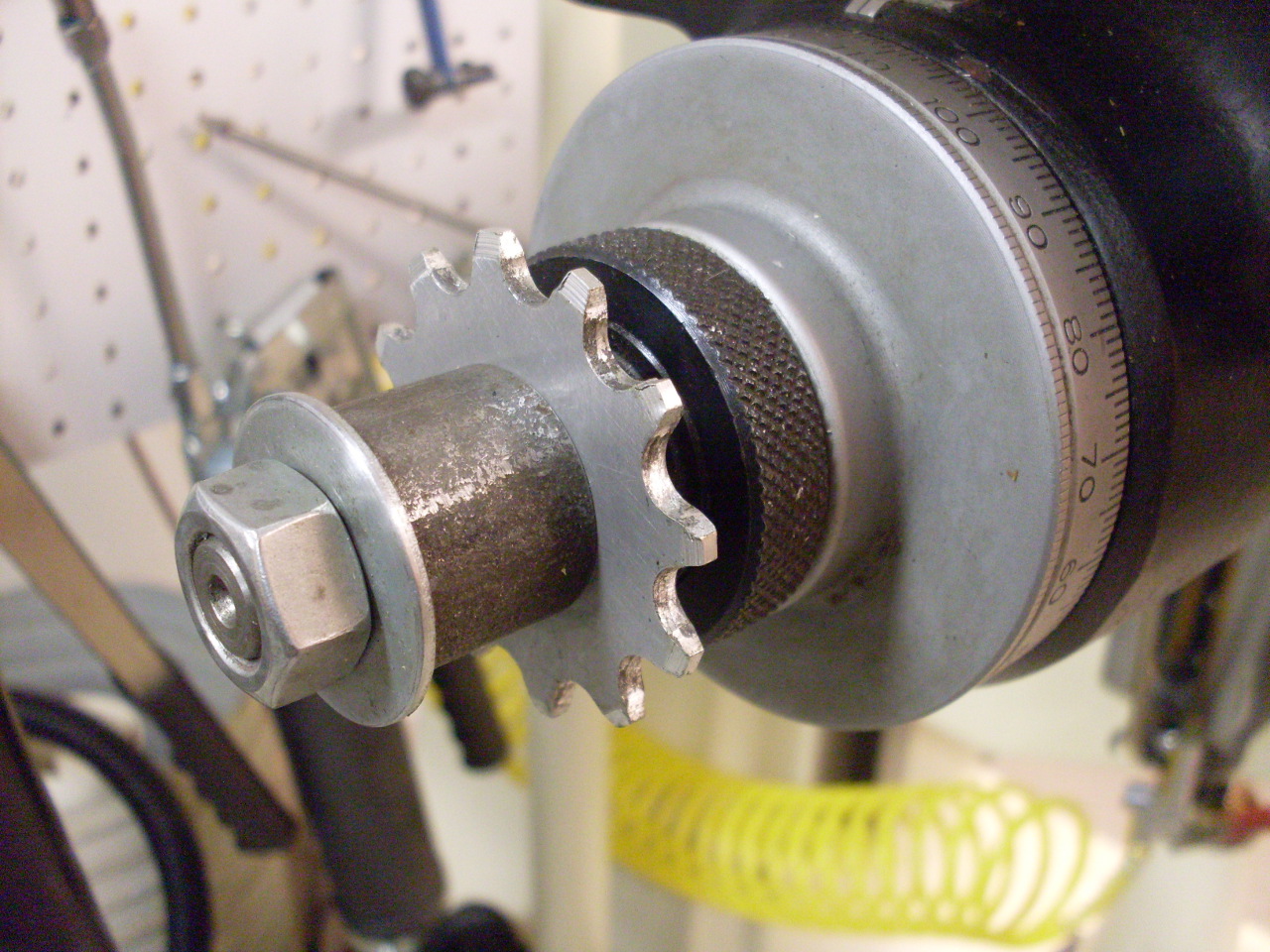

My solution was to take the 4th axis drive from the X lead screw with a

chain and sprocket arrangement. I figured that the sprocket ratio had to

be between 3 and 3.5:1 to get one complete spiral on each spindle bearing

surface. This matched the later Triumph parts. I decided to just use

1/8" bicycle chain because it was cheap and easy to get. I looked for the

right combination of commercial chain sprockets, and found them pretty spendy

for what was probably going to be a one-time use. A little thought and

research encouraged me to just make them myself. I decided to use

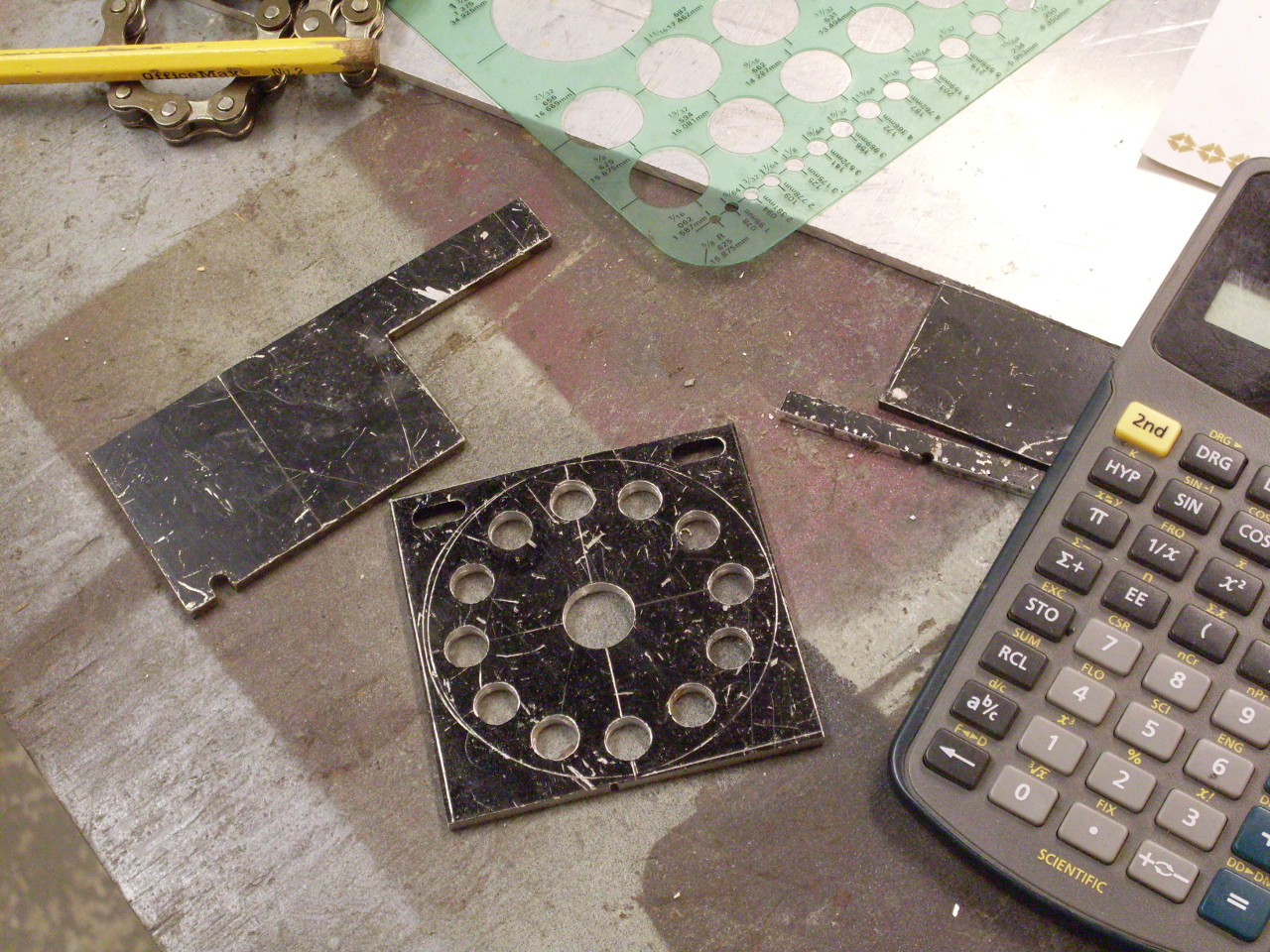

sprockets with 12 and 40 teeth, which gives a good ratio and reasonable sizes.

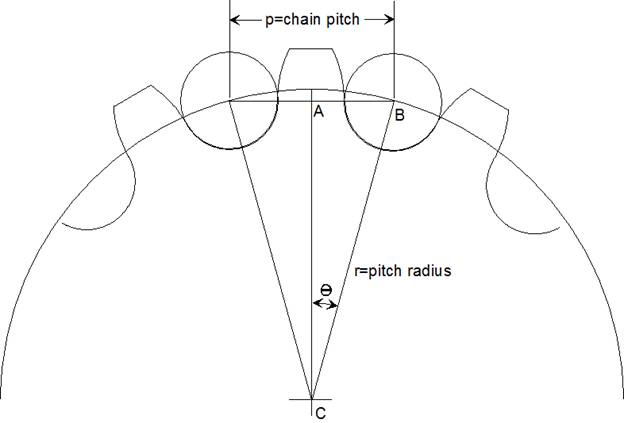

Though there are fairly complex specifications for the tooth shapes on

chain sprockets, the quick and dirty way to do it is to drill holes to fit the

chain rollers (0.300" in this case), spaced around a pitch circle with

spacing to match the chain pitch (0.500"). The teeth are then shaped

to avoid interfering with the rollers as they enter or leave the seats.

Calculating the pitch diameter from the chain pitch and number of teeth

is a pretty basic trigonometry problem (see Sidebar 1)..

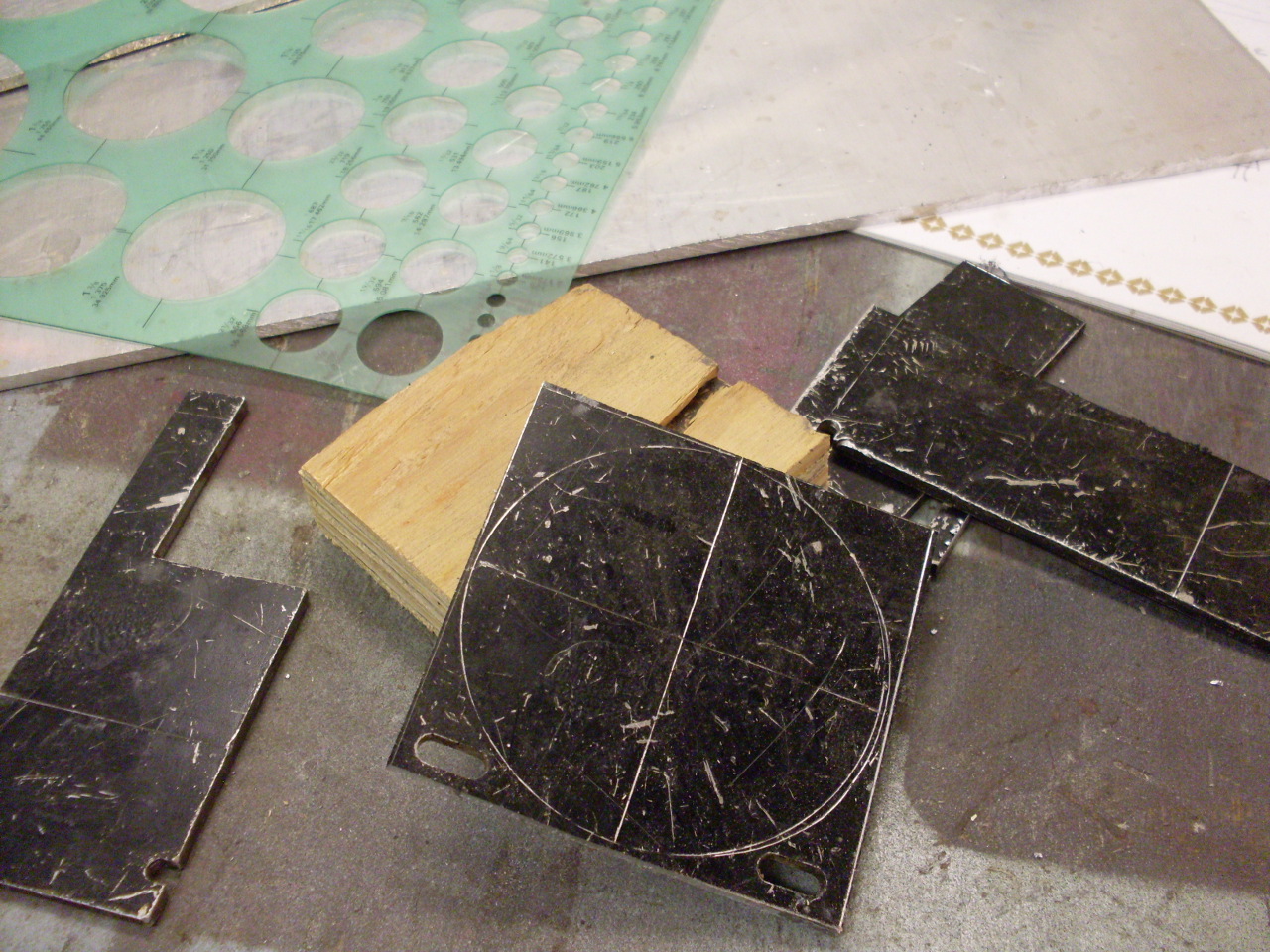

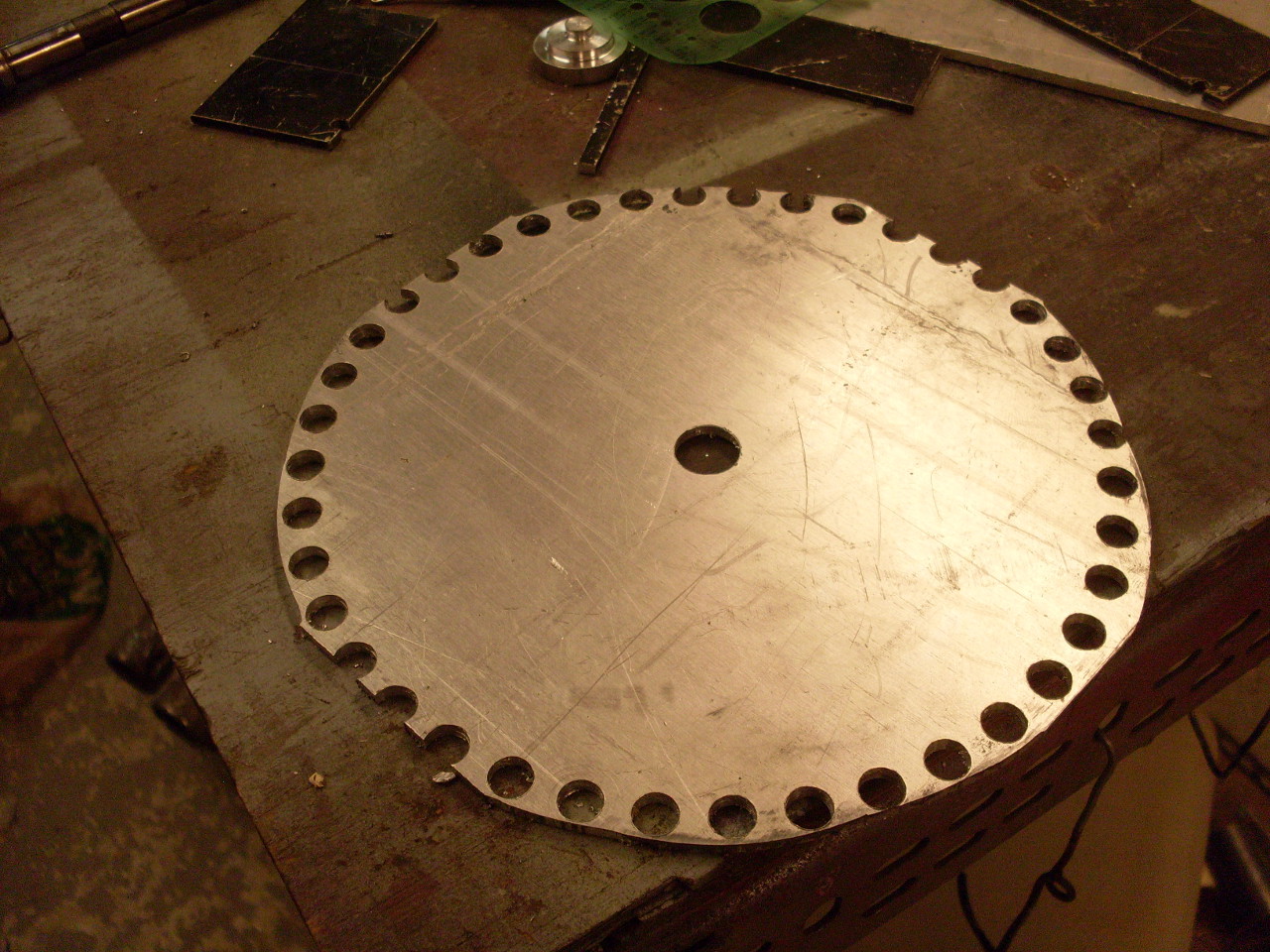

I started with 1/8" aluminum sheet, cut it to rough square

size, and put it into the mill vice. I used my DRO's circle pattern

feature to mark the hole positions around the pitch circle with a spot drill,

then came back around and drilled them with a 7.8 mm drill (0.307"--the

specs say to have the seat diameter slightly larger than the roller). The following pics show the stages of

the process for the small and the big sprocket.

I filed a keyway in the small sprocket and mounted it to

the left end of the X lead screw of the mill table after taking the handle off.

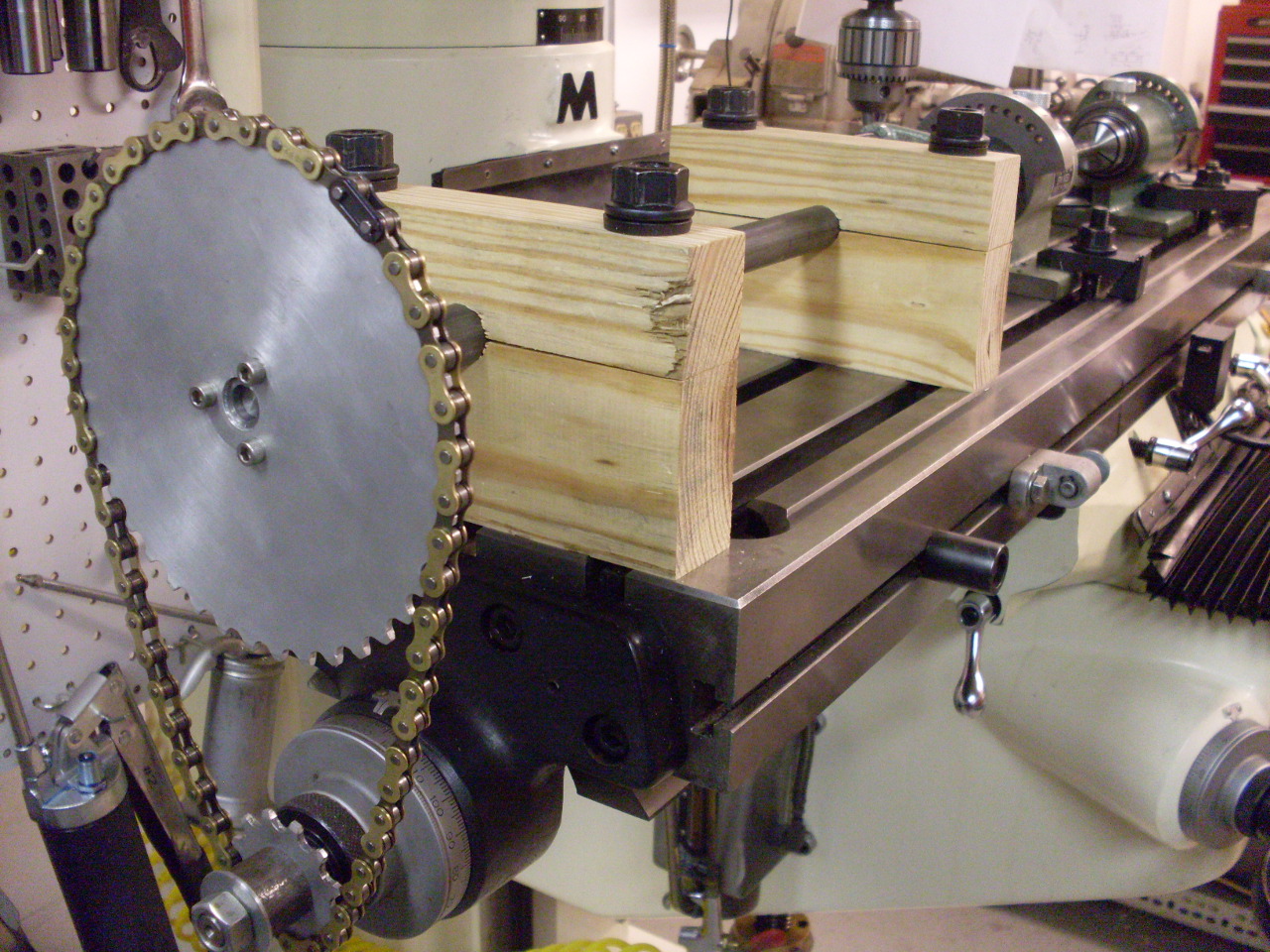

I made a hub on the lathe so I

could mount the big sprocket on a ½” drill rod shaft. The shaft was about 18 inches long to bring

it over near the center of the 49 inch mill table. I used a piece of ½” black iron pipe to carry

the shaft. I bored the ends of the pipe

to accept a 1/2” bronze bushing in each end.

To make sure the bushes were collinear enough not to bind on the shaft,

I made the bores a little roomier than normal, and super glued the bushes into

the pipe with the shaft in place.

I then fashioned two pillow blocks made out of wood to hold the shaft

assembly at the right height above the table (I started as a woodworker—it’s

hard to change old habits).

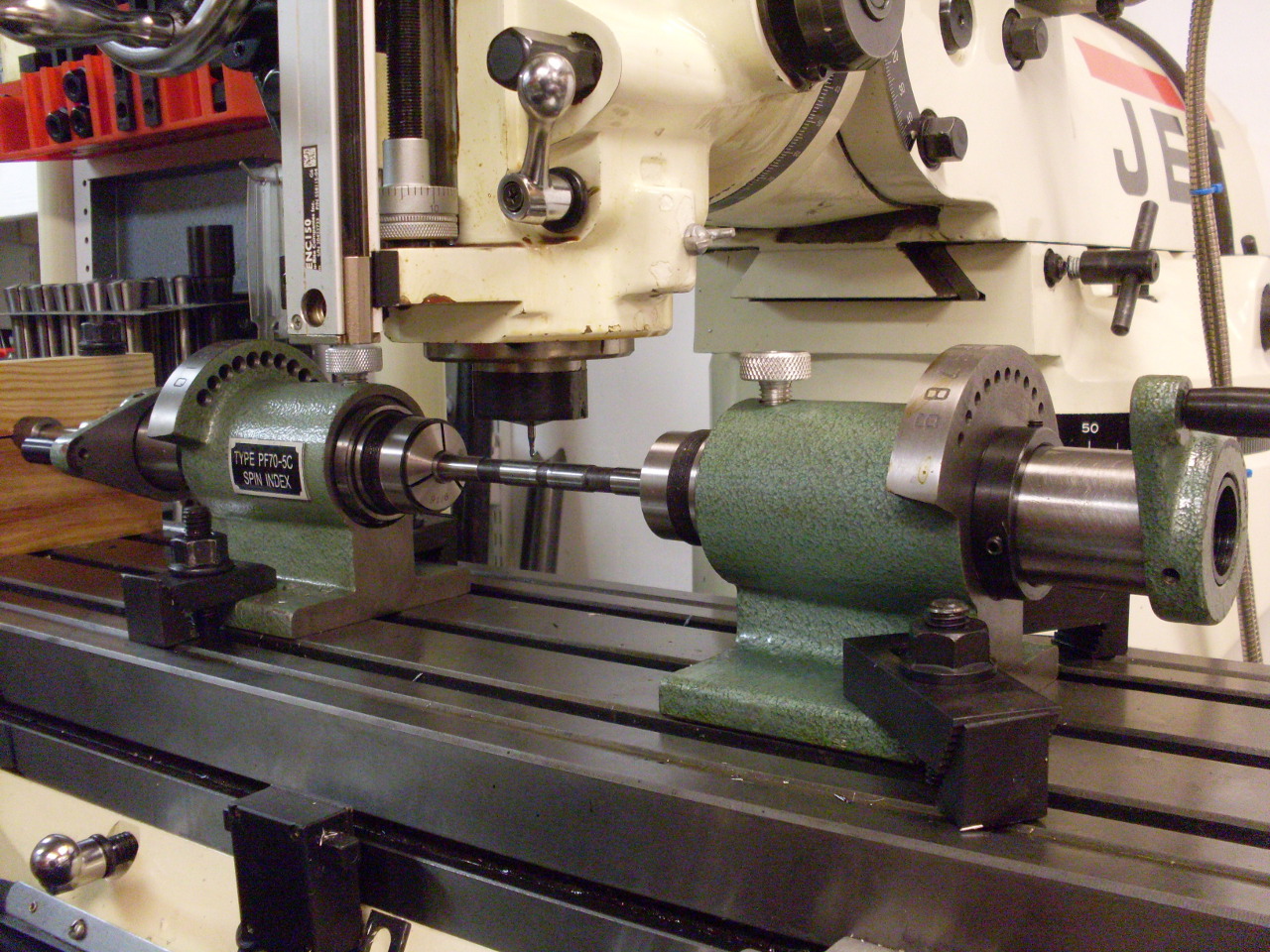

The work (the rocker spindle) is held at each end by one

of those ubiquitous PF-70 spin indexers using 5C collets--3/8" at one end,

and 9/16" at the other.

This is what determined the height of the drive shaft above the table. I

got better clearance on the indexers by taking them apart and reassembling them

backwards. I also took off the index disks. I was pretty amazed

that the height of the work varied by only about 0.002” from end to end.

I was prepared to have to skim the bottom surface of one of the indexers,

but it wasn't necessary.

To

avoid having to be too persnickety about alignment, I

made an "Oldham Coupling" to tie the drive shaft to the left indexer.

The coupling accommodates some shaft misalignment. The

center part of the coupling is Nylon for a smoother

action. One end of the coupling is turned for a snug fit inside

the drawbar

of the left indexer and is fastened with a couple of set screws.

To

avoid having to be too persnickety about alignment, I

made an "Oldham Coupling" to tie the drive shaft to the left indexer.

The coupling accommodates some shaft misalignment. The

center part of the coupling is Nylon for a smoother

action. One end of the coupling is turned for a snug fit inside

the drawbar

of the left indexer and is fastened with a couple of set screws.

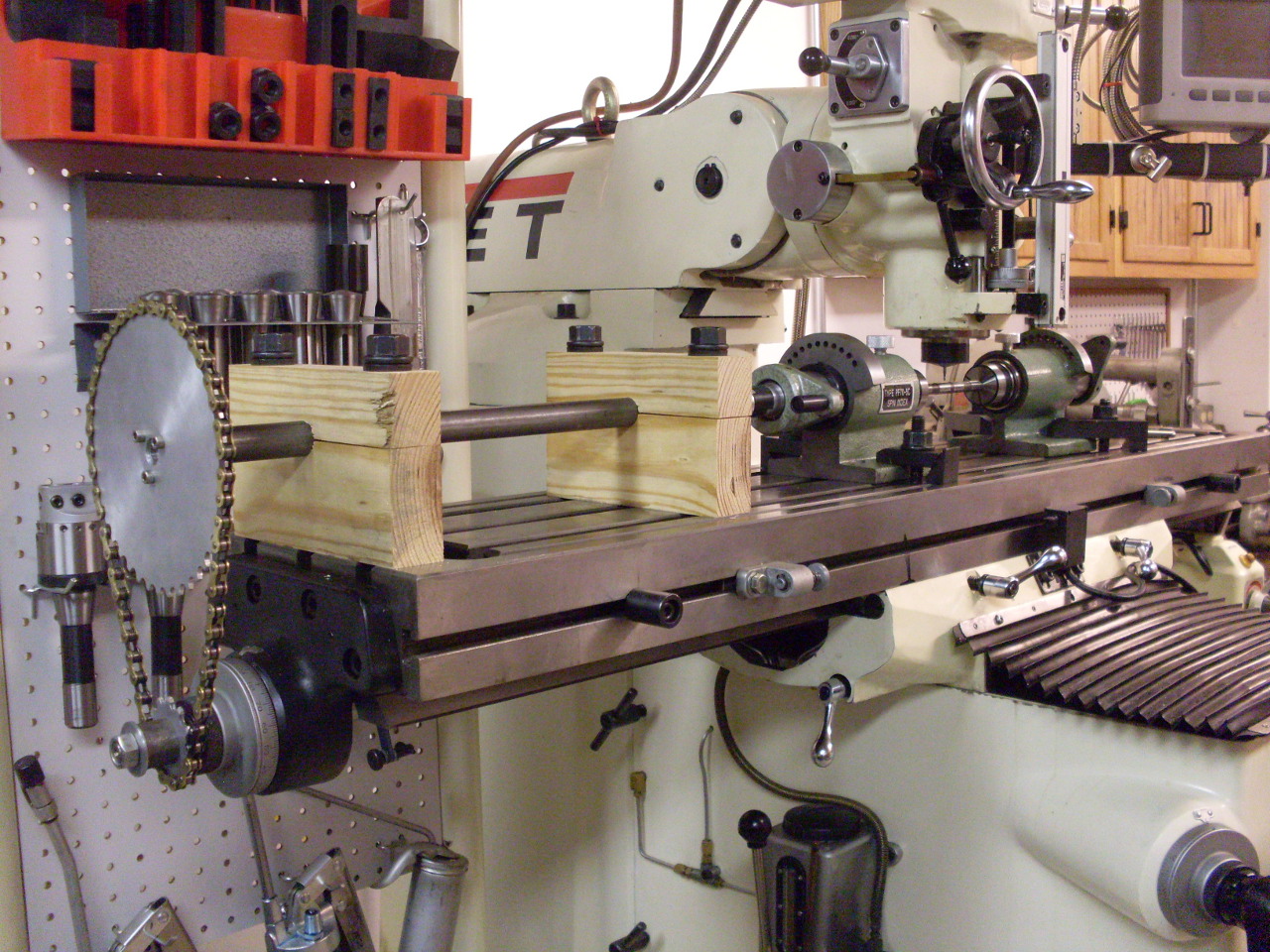

I indicated the work to make it true with the X travel, and tightened

everything down. Here is the

entire setup.

Measuring from later year parts, the grooves needed to be about 0.016"

deep and about 0.065" wide. A little more trig (See Sidebar 2) showed that a

5/64" ball end mill should do the trick, so I ordered a couple of solid

carbide units. I wasn't sure how hard the shaft was or if HSS cutters

would have a problem.

It turned out to be pretty simple to do the actual cuts. I positioned the cutter directly above the

centerline of the work, and, starting in the reduced diameter

areas, fed slowly by hand using the highest speed my mill would do (4200

RPM). The last pic shows the resulting

groove.

After all this, my bike has better lubrication to its

valve train, I've got some new skills and experience, some tooling vendors have

some more money, and my wife thinks I did something useful. Everybody's

happy.

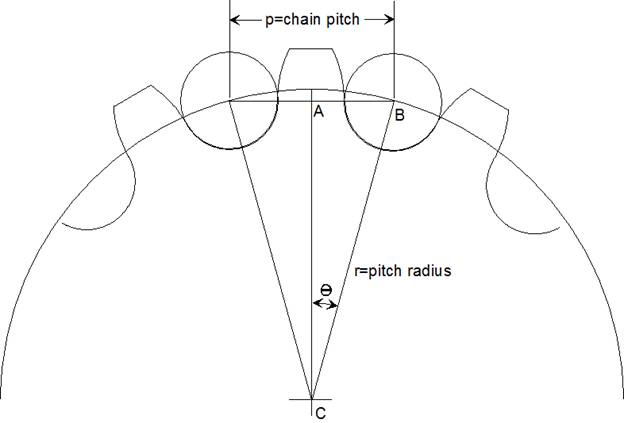

Sidebar 1: Calculating Pitch Diameter

To find sprocket

pitch radius when chain pitch and number of teeth are known:

is one half of the angle between teeth, so, if

n is the number of teeth on the sprocket,

is one half of the angle between teeth, so, if

n is the number of teeth on the sprocket,

.

.

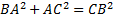

Triangle ABC is a right triangle with AB

equal to half of the chain pitch, and BC equal to the unknown pitch

radius. To find the pitch radius:

.

.

The first formula gives the angle in

degrees, so make sure the calculator is set appropriately for the second

formula.

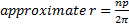

For larger sprockets, a shortcut formula

may be used. The circumference of the

pitch circle can be approximated by multiplying the number of teeth by the

chain pitch, and the pitch radius comes by dividing that by 2π.

.

.

For sprockets with more than 12 teeth, the

error of the approximate formula is less than 1%.

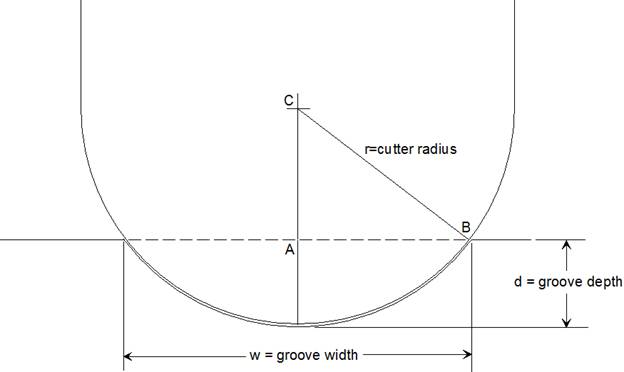

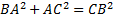

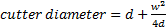

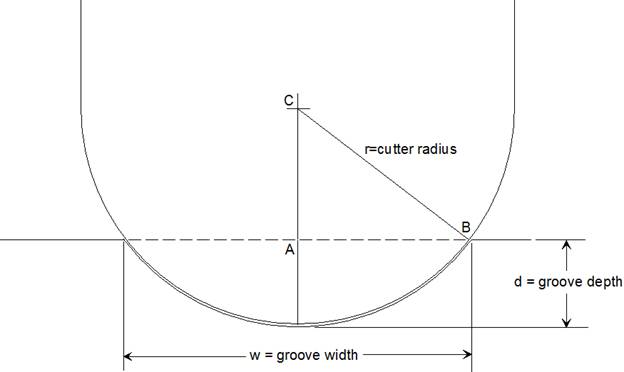

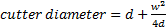

Sidebar 2: Calculating cutter Radius:

What

size ball end mill is required to make a groove of known depth and width?

First, we’ll assume that the groove is

being cut in a flat surface instead on the surface of a shaft. This vastly simplifies the math, and the

error is small.

Triangle ABC is a right triangle with CB

equal to the radius of the ball end mill, BA equal to half of the groove width,

and AC equal to the mill radius minus the groove depth. Using the Pythagorean formula for right

triangles,

,

,

or

A little algebra gives:

.

.

The nominal size of the cutter (its

diameter) would be twice the radius:

.

.

is one half of the angle between teeth, so, if

n is the number of teeth on the sprocket,

is one half of the angle between teeth, so, if

n is the number of teeth on the sprocket, .

. .

. .

.